Client work:

- External Communications (Print Writing)

- Press Release

- Abstract for B2B Conference/Tradeshow Paper

- Internal Communications (Print Writing)

- Trade publication/feature article

- Journalism

- Schlumberger webpage

- Schlumberger webpage

Here’s an internal change communications for Pentair:

This was one of many internal communications I developed to help get the team onboard with the idea of killing the brands to help better manage Pentair’s portfolio. (The company had over 60 brands, which made it complicated to manage, market and sell. The aim was to consolidate the brands so it would have a stronger position in the market. Pentair Valves and Controls was later acquired by Emerson.)

Here’s a newly refreshed product line for Rand Group:

The Rand Group website serves mostly as a lead generation tool. Updating product lines with new and interesting content (along with SEO optimization) is a major component of any ongoing marketing campaign.

Here’s a short piece for an online external communication for ABS:

BASS 400 Jackup Designed with Higher Variable Deck Load

BASS 400 Jackup Designed with Higher Variable Deck Load

ABS has reviewed the design for the BASS 400, a new jackup design with a higher variable deck load. The increased reserve buoyancy provides a higher capacity to assist in the removal of the legs from the seabed. The improvement is the result of a deeper hull, more efficient use of the hull template and an improved weight-to-strength ratio of the legs.

The unit is an independent-leg, rack and pinion design for moderate environments in water depths of 400 ft and drilling depths of 35,000 ft. In the storm elevated condition, the jackup has a 9,000 kip variable deck load. The unit features robust leg design with enhanced chord strength.

In addition, the 142 ft aft leg spacing and 129 ft longitudal leg spacing provide for greater on-bottom stability. The three-legged self elevating drilling unit has accommodations for about 150 personnel.

The BASS 400 is designed for modern pipe handling, new blowout preventer (BOP) requirements and new environmental regulations. Most recent statistics show approximately 400 jackups operating worldwide built to ABS class.

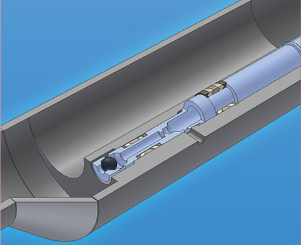

Regulations in a key oil producing region dictated all gas-lifted wells have annulus safety valves. One producer had many wells with failed ASVs, which would have required expensive repairs and shut-down.

- Can wells safely operate with revised procedures and surface valves as back up?

- Is this a safety hazard to personnel due to leaks or explosions?

It was determined the gas-lifted wells could be safely operated using surface (wellhead/x-mas tree) valves and revised operating procedures. The producer successfully petitioned to continue operating the wells under these conditions.

Project Outcome:

- Well failure of gas-lifted wells with ASVs stuck in open positions was examined.

- How long were these wells operated after valve issues were discovered.

- Did gas leaks or explosions result after valve problems were identified.

Estimated valued: >$170 million avoided repairs

Gas Lift Valves As Barrier Devices

Gas Lift Valves As Barrier Devices

Because gas lift valves were considered primary well barrier devices by a North Sea producer, it was necessary to test these valves on a prescribed schedule. The costly and dangerous testing procedure involved well intervention and setting plugs to discover potential leaks.

- Are gas lift valves really barrier devices?

- Would well safety be compromised if gas lift valves failed?

- Are gas lifted wells with annulus safety valves and SCSSVs actually safer when gas lift valve testing is not required?

Findings from WellMaster queries were used in a quantitative risk assessment to address key questions. What percentage of well blowouts occur during the production phase versus the drilling, completion or work-over phases? What is the relationship of offshore well blowouts to gas lift valve failure? What is the relationship of well blowouts to ASV failure? What is the relationship of well blowouts to SCSSV failure?

Project Outcome:

- Very small percentage of well blowouts occur during the production phase

- No correlation was found between gas lift valve failure and blowout rates

- Producer was able to change its testing procedures for gas lift valves

Estimated value:

saving production, well intervention costs and increasing well reliability

Like what you see? Let’s work together!